UV PRODUCTS

UV PRODUCTS

|

|

|

|

Liquid Sugar UV Systems |

Liquid Sugar UV

Disinfection

Liquid Sugar UV

Disinfection

Systems -

Key Benefits

- For instant disinfection of liquid sugar and syrups

- Proven chemical free UV disinfection

- Effective on a wide range of microorganisms including thermophiles

- Economical to operate and maintain

- Low cost

- Easy to relocate

Liquid Sugar UV Brochure /PDF/

Liquid Sugar UV Brochure /PDF/

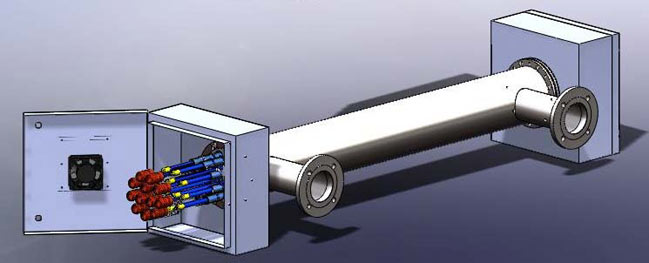

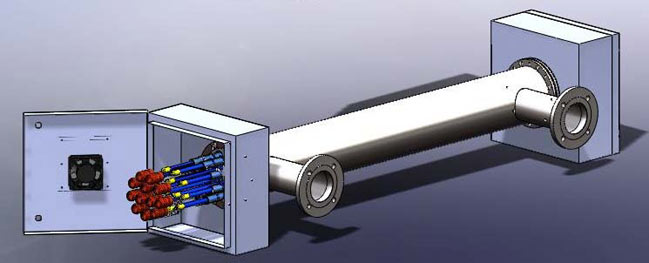

The Liquid Sugar “LS” UV systems are designed to

treat flows of up to 200GPM (gallons per minute) per vessel.

Liquid sugar, which has very low UVT (Ultraviolet Transmission or Transmittance), passes as thin film over tightly

packed UV lamps where it is exposed to powerful germicidal ultraviolet light

and is disinfected. The germicidal ultraviolet lamps are oriented in tight

clusters to maximize UV exposure at very low UV transmittance levels - as

low as less than 1% UVT.

The liquid sugar UV systems are specially designed to treat liquids in a thin

film manner - with the lamps close together to optimize the

disinfection process. They are designed to treat opaque and thick liquids,

sucrose syrups with high osmotic pressure (brix 25-67), glucose, juices and other base

materials.

While the thin film UV systems have been used primarily for disinfecting liquid

sugars, where microorganisms can exist in spore form and can reproduce once

introduced into the food and beverage lines, they have been proved effective for

treating fruit juices and pharmaceutical base liquids.

Thin Film UV Systems Applications - Food processing Beverage plants, Pharmaceutical, Honey manufacturing Apple cider disinfection, Cosmetics

|

|

IL-LS UV Disinfection Systems Technical Data |

Liquid Sugar

UV Systems |

Flow Rate* |

Electrical |

Replacement UV Lamp |

Quartz sleeve |

Power |

Dimensions

with cooling shrouds |

|

IL-LS-300-5 |

10GPM |

120 or 220V

50/60Hz |

L-024433 (5) |

Q-050232 |

420W |

30” x 5” |

|

IL-LS-300-12 |

35GPM |

120 or 220V

50/60Hz |

L-024433 (12) |

Q-050232 |

1,020W |

30” x 10” |

|

IL-LS-5000-12 |

75GPM |

220V

50/60Hz |

L-020760 (12) |

Q-051064 |

2,040W |

80” x 10” |

|

IL-LS-5000-20 |

100GPM |

220V

50/60Hz |

L-020760 (20) |

Q-051064 |

3,400W |

80” x 14” |

|

IL-LS-6000-16 |

125GPM |

120 or 220V

50/60Hz |

L-549460 (16) |

Q-0566064 |

5,600W |

80” x 18” |

|

IL-LS-5000-36 |

150GPM |

220V

50/60Hz |

L-020760 (36) |

Q-051064 |

6,120W |

80” x 20” |

|

* Flow rates

shown as a general guideline at 67 brix. Actual flow rates will

depend on the specific UVT of the liquid sugar or syrup

and other project conditions.

Each liquid sugar UV system is quoted on a "per case" basis. |

5000 Series

Ballast: E-07230B (220V)

6000 Series Ballast: E-300A2B |

|

STANDARD FEATURES

• 316L electropolished high purity vessel

• Stainless steel remote ballast control center with lamp out status and run

time

Liquid Sugar / Sucrose

• Low-pressure 10,000-hours UV lamps (high output and amalgam)

• Electronic ballasts in 120V or 220V

• Sanitary fittings (inlet/outlet, drain and sample ports)

• Flexible mounting

OPTIONAL AND CUSTOM FEATURES

• Fan cooling - lamps may need to be cooled to maintain maximum output

• PLC monitoring

• Chemical cleaning tanks (system is designed for CIP standard practices)

• UV monitoring is available for plants that want to have a higher level of

security

• We have the ability to customize the UV system for any installation. Our

engineers can design a custom UV product to meet the installation

requirements.

Liquid Sugar UV Brochure /PDF/

Liquid Sugar UV Brochure /PDF/

Contact American Air & Water for Thin Film UV systems

Contact American Air & Water for Thin Film UV systems

|

![]() Liquid Sugar UV Brochure /PDF/

Liquid Sugar UV Brochure /PDF/ ![]() Contact American Air & Water for Thin Film UV systems

Contact American Air & Water for Thin Film UV systems